All Systems Go in Brandenburg

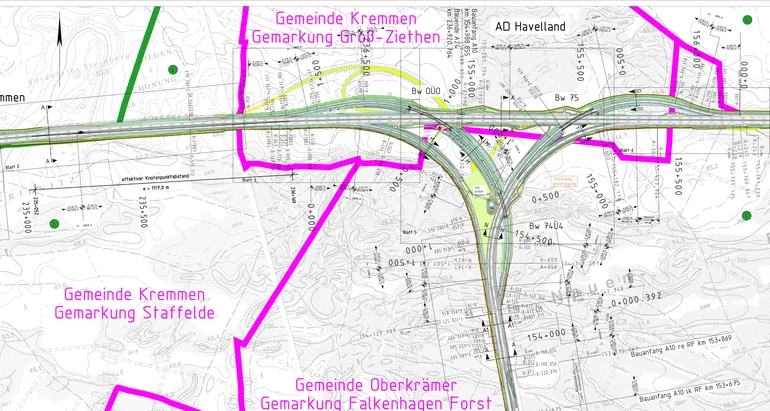

The Havelland motorway junction joins the A10 and A24 federal motorways and plays an important role in the national motorway network. Unfortunately it's plagued by congestion and tail-backs. Solving this problem will not only improve traffic flow but should also foster the regional economy. The company VIC Verkehrsanlagen GmbH has been tasked with designing the enlargement of the junction – a juicy challenge for surveyors, planners and card_1.

Although the existing junction is up to the task, the left-hand trumpet and its extremely narrow design parameters do not fulfil today's requirements. The lack of hard shoulders along the on/off ramps in particular pose a safety hazard. The existing entry and exit roads can only just cope with the present, let alone forecast, traffic volume. Any increase in volume quickly leads to congestion and long tail-backs which significantly impairs road safety. Despite re-surfacing with asphalt, the road surfaces also show signs of deterioration, damage and ruts. As an important inter-regional junction connecting international routes and the Berlin Ring, it is imperative this be improved. It must in future be able to deal with up to 65,200 vehicles per hour (forecast) of which 23.3% may be HGV.

The Solution

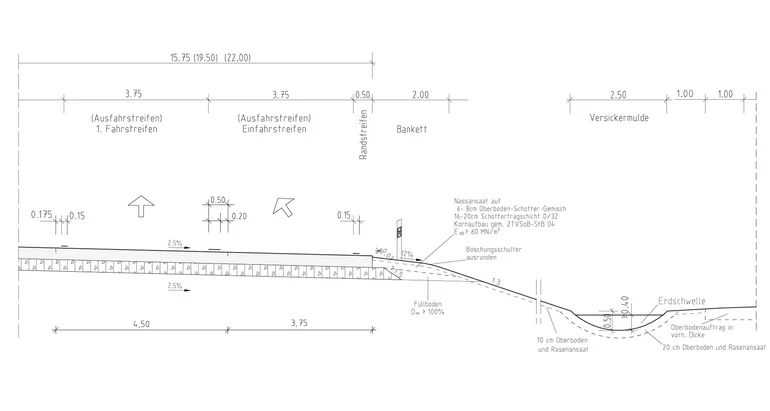

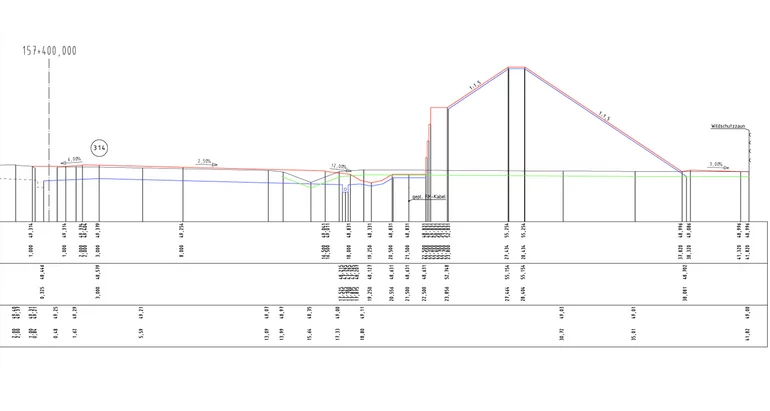

The Havelland junction will be extended to include a semi-direct carriageway for vehicles turning left into and out of the junction. The A24 will flow into the A10 (northern Berlin Ring) while the A10 (western Berlin Ring) will be joined to the A24/A10 (northern Berlin Ring) by connecting ramps. Traffic forecasts and the Guidelines for the Design of Motorways (RAA, Richtlinie für die Anlage von Autobahnen) show the need for two access ramps between the Werder and Wittstock/ Dosse junctions and in the opposite direction a dual carriageway based on the standard cross-section Q2. For the access ramp connecting the Oranienburg and Werder junctions the transition of a carriageway lane into a connecting ramp and vice versa meant a two-lane carriageway plus hard shoulder (RQ 29.5/2) into a three-lane carriageway plus hard shoulder (RQ 35.5/2) and vice versa. The Werder towards Oranienburg junction connecting ramp starts off as a RQ 35.5/2 cross-section. After about 450m this will be widened along a 100m long strip resulting in a RQ 29.5/2 cross-section in order to accommodate a two-lane access road in compliance with the Guidelines for the Design of Motorways (RAA, Richtlinie für die Anlage von Autobahnen) RAA, type 4. Each road is being designed with a 30cm thick concrete substructure in the standard cross-section.

Havelland Junction Structures

The junction's shape requires the design of three flyovers. The first flyover to cross the A24 will be a five-span, continuous girder bridge with a total span of 197.50m. The design specifies a single-cell box composite steel cross-section. A second bridge over the connecting ramps between the Werder and Oranienburg junctions will be a longitudinally prestressed structure with a single-webbed T-beam cross-section and a total span of 100.6m. The third structure crossing the A10 will be a four-span continuous girder bridge spanning a total of 148.50m, again with a single-cell box composite steel cross-section.

The Kremmen Connection

Re-doing the Kremmen connection on the A24 is an integral part of the project. As per the existing conditions it will continue to look like half of an asymmetrical clover leaf in order to preserve the south-west quadrant of oak trees. The ramps will join the B273 (federal highway) at a roundabout in order to facilitate traffic flow. The flyover leading to the A10 will be constructed as a "Bear Bridge", designed to act as gateway to the Berlin Ring and the city itself. As a memorial to the historical gate houses, the relief of a bear will grace the new structure so that in future, all radial motorways approaching Berlin will enter through the "Bear".

New Drainage

Surface water will be drained via the verges and embankments into drainage swales. Any access ramps on embankments will have a curb in order to prevent erosion. Carriageway run-off will drain into v-shaped gutters running into roadside gullies. From there, via cascades, it will flow down into swales at the foot of the embankment to then percolate away. Where construction starts (A24) and at the Oranienburg – Werder junction's access ramp, surface water will be drained into the median strip, also via v-shaped gutters. A rainwater channel will take the surface water in both sections and feed it into settling basins before going to drainage basins. A cross-drain is planned to improve drainage on areas of tightly curving roadway on the A24.

Traffic Flow During Construction

Maintaining traffic flow during construction was a huge challenge. Developers planned to keep traffic down to two lanes in either direction without hard shoulders along the A10 and A24 construction sites. This required widening some road sections to 12.5m, creating provisional lanes, ramps and median strip crossings, and temporarily changing the motorway access roads. The road safety measures then had to be adapted to suit the temporary conditions.

Noise Protection

A 6m-high noise protection barrier will be erected along 800m of the northern section of Berlin Ring's outer circumference. In an effort to minimize the amount of land required, the embankment alongside the motorway will be reduced by means of a Gabion wall.

Designing with card_1

card_1 Version 7.7 was used for the initial planning phases then was seamlessly updated to the current Version 8.4 in 2012 and was used from start to completion of the execution planning phase. The project's complexity posed a tough challenge for the cross-section planners, particularly as right from the start they aimed to design the main A10 and A24 routes, including all access roads, without manual intervention. In this they were aided by their own application developed using CardScript: an extremely flexible 'element' or 'lane' method with which the planners could master all tasks. The use of uniform point numbers in the cross-sections meant quick and easy generation of the Base Map via a standardised allocation table. The technique of using a global layer underpinned the entire project allowing e.g. many plans to be easily generated at different scales. Being able to work and view projects of this dimension globally greatly improves efficiency as does the 3D Project View which shows the design's complex interdependencies.

Planners can use this to visualise and appraise how the various access roads join the main roads and then use these images to make clear presentations.

Conclusion: card_1, used throughout the entire planning phase of this complex undertaking, could solve all necessary tasks. Constant updates and new functions were a huge advantage in terms of the data volume processed and the improved 3D Project View.

Contractor:

VIC Verkehrsanlagen GmbH

Sauerbruchstraße 12

14482 Potsdam

Fon +49 331 7496-131

Fax +49 331 7496-200

Mail to VIC

www.vic-gmbh.de